To continue on my recommended upgrade and modification list .

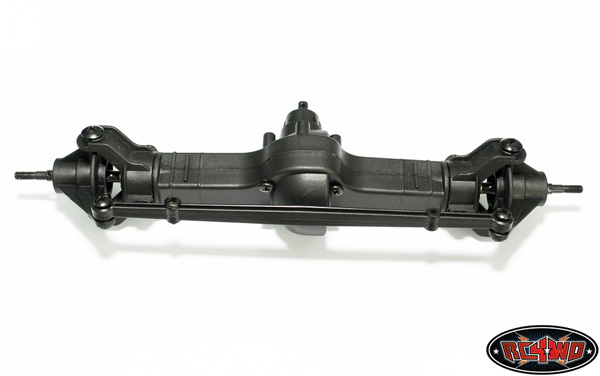

I figure the next area I want to focus on is the front and rear axles .

All over the internet you can read about people who have broke axle housings on the Ground Pounder but to be honest I feel most of the breakages could easily be avoided by making a few modifications .

Modification number 1:

Drill out all the screw holes in the axle halves so that 3 mm screws will pass through with little to no resistance . Next install longer 3 mm screws that will allow a small diameter washer and a nut to be installed .

Reason's

The holes in the axles are small and require the screws to be threaded through both halves of the assembly .

Drilling out the holes speeds up assembly.

I also feel this clamps the axle halves better and increases the rigidity of the assembly and makes the halves act more as one unit .

Modification number 2:

Shimming the differential and ring and pinion is the next modification I would recommend . Shimming the ring and pinion gears is about give and take . I recommend adding shims to the side bearing of the differential till there is no side to side play . I then move shims from left to right and right to left till the pinion and ring gear mesh with just a tiny bit of play . Adding shims behind the pinion can move the pinion inward increase the contact area and the strength of the ring and pinion . So moving the pinion inward is a good thing . The main cause of compromise in shimming is binding when the steering knuckles are turned as the dog bones are a couple millimeters 2 long for perfect differential placement , at least in my experiences . As a finishing touch I also shimmed the pinion on the outside so it can not move inward by putting a brass bushing between the bearing and the drive shaft yoke . I sanded the bushing to make it the right thickness .

Modification number 3:

Clean the Grease out of the differential and fill them with silicon oil . Currently I'm using 5000 wt hot bodies diff oil in the rear and 3000 wt HB oil in the front . "I'm considering going to thicker diff fluid in the future" Even using the 3000 wt and the 5000wt oils I can say stability and drive ability have increased greatly due to the reduction in tire ballooning when weight shifts off a tire and for mud and snow it will keep you chugging forward with authority .

.jpg)

.jpg)